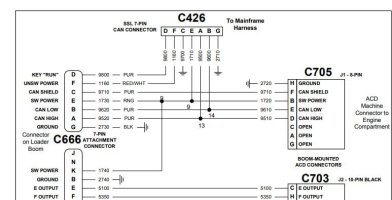

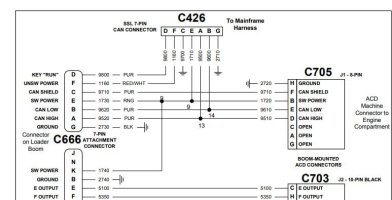

Hey guys. Have not posted in a while, but this topic is near and dear to my heart. As a manufacturer and good long term customer of Bobcat, I have been amazed at how they have developed a system to try and keep people from connecting non-Bobcat attachments to their machines. This is supposed to keep people from buying attachments, but it is in fact keeping people from buying Bobcat branded machines. The final straw was in March when I had a new A770 delivered with a 14 pin kit installed. They ran the wiring along the top of the boom. When I contacted Bobcat engineering, they said they were doing away with the 14 pin systems. I then heard from a customer with a new Toolcat who bought the machine on our suggestion, then Bobcat told him they could not use our attachments because they would not cover the warranty and they would not supply him with a 14 pin set-up. That was it! I was fed up. I have developed a Can-Bus translator that alleviated the need for the 7 pin set-up on the attachments. Just plug it into the 7 pin connector, stick it on the side of your boom and it gives you two 12 volt, 15 amp switched outputs using 2 pin Deutsch style connectors. These connectors are inexpensive, sealed, robust and easy to find should you break one. This means you are not stuck buying 7 pin connectors from Bobcat for over $100 each. Just buy our little box and do what you want. The first output works from the left stick, left and right toggle switch. The second circuit reacts to the left stick cylinder switch toggle. This should work for 99% of the attachments that are out there. This is a properly interfaced, protected circuit that will not damage your machine. I have no doubt that BC will tell you differently. I have heard it all from their dealers about my attachments so I have no doubt you will be told that this will blow up your machine, void the warranty, blah, blah blah. Just note that I have been at this for 17 years, know skid steers and my background is electronics. This was a simple circuit for me to design, but it just took BC getting me mad enough to want to take action. When it came to them jury rigging my own machine, then that was it. The retail price on this will be $295. I am selling the initial run for $249 as I am trying to boost the first run numbers in an effort to get the PCB cost down. If you mention Skid Steer Forum when you order, I will give you another $10 off. The hardest part has been getting the 7-pin connectors made. Otherwise I would be paying over $100 per connector which is a joke. In the future I will have the connectors in stock. Check out out ingenius plug and play anti theft device for Bobcats as well.