You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bobcat Electrical Attachment Hookup Explained In Detail !!!

- Thread starter Bobbyboy

- Start date

[email protected]I would like more info on ur device and possibly purchase trying to marry a timberline treeshear to Bob cat and need to purchase something

Why are the relays neccessary couldn't it just be wired as a 12 volt switch not totally familiar with 22 volt systemsRod

That is exactly what i did.

Mine has 3 thumb switches and a trigger switch, the trigger is a dual pole, pull for continuity, pull again to open the circuit.

The other are all 3 pole switches, off in the center and on to either the left of the right.

2 of these switches are momentary, the other stays where you put it. So I tied into the 2 momentary ones, each has 3 wires, a center and one for each side. I just wired these to 4 spdt relays so the switches would only see a 1/10 amp load.

I use the for up/down and left / right on my stump grinder and to control the chute rotation and deflector on my snow blower. Works great. The loader never noticed anything changed when I uplugged the harness at the bottom of the steering lever on my 773G, I going to try it this winter on my S185.

Also my Ls 160 had no left steering lever switches, so I bought the Bobcat switch for $114 and fit it to the NH as well

Ken

12 not 22Why are the relays neccessary couldn't it just be wired as a 12 volt switch not totally familiar with 22 volt systems

Jyuma1

Well-known member

This is a very old post.I would like more info on ur device and possibly purchase trying to marry a timberline treeshear to Bob cat and need to purchase something

This sounds like what I want to do did u leave the wire harness connected or did u disconnect just leaving 2 pin counter to supply power to the switchesRod

I'm not certain, however I believe you would still have to buy the #4 combination 7/14pin harness and you may have to remove your non combination harness to plug the new harness in.

I just tapped into the the wire harness to access the left handle switches and made my own harness with relays and run it out to a trailer plug by the hydraulic couplers on the boom. This gives me 4 momentary hots to control attachments along with a steady ground.

I intend to avoid like the plague any 7 pin bobcat attachments, as they only work on Bobcats machines. (unless you can rewire)

Where as every other manufacturer, Cat Case Deere and the hundreds of aftermarket attachment manufactures make attachments that do the exact same job with simple power or/power off controls. If the day ever comes you want to sell an attachment, it is nice to know it fits all brands, including Bobcats, where as the 7 pin attachment fit only Bobcat

Ken

What size relays would u be usingKen,

Thanks. You've given me a great idea. The left control handle (standard controls) on my skid has two vertical rocker switches. The one on the left is for the directional lights option which I don't have, so it's unused. The one on the right is for some attachment control that doesn't apply to any attachment I currently have so that one is also available for some other use. I think these are the two switches you are referring to, correct? I should be able to do the same as you have done and tee into the correct wires in order to be able to use these switches for any custom use that I want. That way I would not have to buy anything from Bobcat - at least that's what it seems.

The only Bobcat attachment I have that uses any attachment control is my SB200 snowblower. That uses the left vertical rocker switch on the right control handle and the central horizontal switch on the left control handle. Those functions should not be affected by my custom use of those other rocker switches. I have a Bobcat service manual with the wiring diagrams so I should be able to select the correct wiring to tee into. Finding the appropriate wires seems to be the hardest part. The relays, custom wiring harness and external weatherproof plug should be a piece of cake. Do you see anything wrong with this thinking? I'll wait until next year before attempting anything like this as the skid is only a couple of months old and under warranty.

Rod

Phil314

Well-known member

It would help if you told us what machine you have.What size relays would u be using

And how many pins the attachment has.

Have a T 300 attachment has 2 pins single soloniodIt would help if you told us what machine you have.

And how many pins the attachment has.

Phil314

Well-known member

If that's the only attachment you need to control, then it wouldn't be too hard to just run wire from a 12v source to a switch in the cab and out to the attachment. Bypass the bobcat controls all together. Wouldn't be that hard. It's what I did on my 1845c. Wouldn't need a relay, just a good 10-20 amp switch.Have a T 300 attachment has 2 pins single soloniod

Or you could by something like this if you don't want to build it yourself.

SG-RC-2BC - Genius - 2 Output Remote Control - Deutsch | Skid Steer Genius

Genius Remote Control - 2 Port. Minimal set-up allows you to be controlling your attachments in minutes.

Or if you plan to run other non-bobcat attachments in the future, you could get this. More $$, but easy install and able to control a wide variety of attachments.

SG-CB-4008 - Genius 7 Pin (4 Output) | 8 Pin Output Controller For Bobcat® Loaders, Toolcat & Versahandler - 4 Port | Skid Steer Genius

Bobcat® Compatible 7 Pin to 14 Pin Controller fits Skid Steer Loaders, Telehandler and Toolcat.

Thanks for ur response I was thinking along those lines but somebody else had mentioned relays . Just need to identify wires powering the control head and run them to the battery I would assume Bob cat switches can handle 10 amps to 20 amps if not no big deal if I burn them out not being used for anything anywayIf that's the only attachment you need to control, then it wouldn't be too hard to just run wire from a 12v source to a switch in the cab and out to the attachment. Bypass the bobcat controls all together. Wouldn't be that hard. It's what I did on my 1845c. Wouldn't need a relay, just a good 10-20 amp switch.

Or you could by something like this if you don't want to build it yourself.

SG-RC-2BC - Genius - 2 Output Remote Control - Deutsch | Skid Steer Genius

Genius Remote Control - 2 Port. Minimal set-up allows you to be controlling your attachments in minutes.www.skidsteergenius.com

Or if you plan to run other non-bobcat attachments in the future, you could get this. More $$, but easy install and able to control a wide variety of attachments.

SG-CB-4008 - Genius 7 Pin (4 Output) | 8 Pin Output Controller For Bobcat® Loaders, Toolcat & Versahandler - 4 Port | Skid Steer Genius

Bobcat® Compatible 7 Pin to 14 Pin Controller fits Skid Steer Loaders, Telehandler and Toolcat.www.skidsteergenius.com

Phil314

Well-known member

Depends on which switches. If it's one of the larger rocker switches, then you are probably ok.Thanks for ur response I was thinking along those lines but somebody else had mentioned relays . Just need to identify wires powering the control head and run them to the battery I would assume Bob cat switches can handle 10 amps to 20 amps if not no big deal if I burn them out not being used for anything anyway

If it's one of the switches on the control handles, they probably will not handle 10 amps.

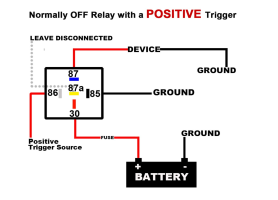

In that case you would need to add a relay, that's not hard and they are cheap.

Just any 30/40amp auto relay would be fine.

Also depends on how much current your attachments coil draws. You could measure that.

That's why I suggest bypassing the bobcat stuff all together and just use a separate rocker switch.

Then you don't need a relay and it's dead simple to wire up.

Yeah I

Was wanting to use a switch on control handle just to keep it neat so I guess I will go with a relay Thanks for ur inputDepends on which switches. If it's one of the larger rocker switches, then you are probably ok.

If it's one of the switches on the control handles, they probably will not handle 10 amps.

In that case you would need to add a relay, that's not hard and they are cheap.

Just any 30/40amp auto relay would be fine.

Also depends on how much current your attachments coil draws. You could measure that.

That's why I suggest bypassing the bobcat stuff all together and just use a separate rocker switch.

Then you don't need a relay and it's dead simple to wire up.

Phil314

Well-known member

Perhaps somewhat related to this topic, on the bobcat t550, are the joystick toggles that send the voltage to the implement magnets on a relay? I lost all voltage to the 7 pin harness going to a bobcat v-blade. Any suggestions to diagnose? Thanks.

Phil314

Well-known member

7 pin harness is a digital signal on 2 of the pins. I think there is also a 12V pin.Perhaps somewhat related to this topic, on the bobcat t550, are the joystick toggles that send the voltage to the implement magnets on a relay? I lost all voltage to the 7 pin harness going to a bobcat v-blade. Any suggestions to diagnose? Thanks.

With that, the joystick toggles/buttons send a signal to the computer, the computer then send a signal out the 7 pin connector.

So they are not directly connected.

Do you have any error codes?

If no, I'd start by checking the wiring harness at the back of the machine where the 7 pin harness connects to the main harness.

Check for loose, corroded, pinched wires.

Is everything else on the machine working?

Phil314, everything else works as it should. What got me looking into this was a broken Oem 7pin trident connector on the machine, which would no longer hold the plow connector on the twist pins. I replaced the 7 pin harness on the machine with the expensive bobcat part, through the boom, to the back engine bay. When I first hooked up the v blade, the wings seemed to try to respond but stalled with little movement. I then notice a wire to one of the hydra force 12v magnet solenoid was broken. I replaced the magnet. Now nothing. How do I check trouble codes on the t550 display? Thank you!

Phil314

Well-known member

If you've got the deluxe keyless display, you can go through the pages on the right display screen and one of the pages will list all the trouble codes.

If you've got a key ignition, then the left display should show a diamond with exclamation point symbol and show the trouble code.

You may have to push and hold the head light button for 2 seconds when the alarm sounds when you turn the machine on.

Since you say everything else works, I'm guessing you won't have any trouble codes.

Sounds more like your problem is still with the 7 pin harness or the v plow.

You sure the vplow is working? Any other attachments you could try.

I'd probably also try to get the pinout from bobcat and try to check that your getting some kind of 12v or signal at the connector.

Any chance it's the wrong harness for your machine? But I would think they are fairly standard on the M series.

If you've got a key ignition, then the left display should show a diamond with exclamation point symbol and show the trouble code.

You may have to push and hold the head light button for 2 seconds when the alarm sounds when you turn the machine on.

Since you say everything else works, I'm guessing you won't have any trouble codes.

Sounds more like your problem is still with the 7 pin harness or the v plow.

You sure the vplow is working? Any other attachments you could try.

I'd probably also try to get the pinout from bobcat and try to check that your getting some kind of 12v or signal at the connector.

Any chance it's the wrong harness for your machine? But I would think they are fairly standard on the M series.

I got this code when pushing the light button as you advised.

I don't have another attachment that takes electric over hydraulics. I do have the old harness ( whose issue was broken retainer clips for the attachment connector) . I will try to attach the old harness from the machine for giggles.

I don't have another attachment that takes electric over hydraulics. I do have the old harness ( whose issue was broken retainer clips for the attachment connector) . I will try to attach the old harness from the machine for giggles.