bobcatzack

Well-known member

- Joined

- Oct 16, 2022

- Messages

- 122

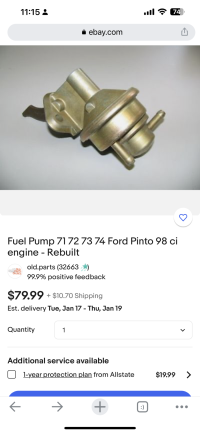

Hi Pete, those are incredibly encouraging words!! Sometimes I start thinking to myself that I may have gotten this far by chance, and if I try to proceed any further (I.e. messing with pistons/crankshaft etc) I might begin to cause more harm than good, and might come to a point where there might not any turning back to where things were (at the least, the Bobcat used to crank and start!). On top of that, any machine shop I am calling in the area are backed up on engine repair work for about 2 months.Hey Zack, just for the record, that thing you're calling fuel filter is actually a fuel pump. Not that that really changes anything, I'm just trying to help you identify parts. Also, you mentioned fuel solenoid. I didn't see a solenoid in there. If it matters, post a pic of what you're calling a solenoid. Again, only if it matters to ya.

Guys he's doing this in his garage all by himself. He'd never done anything like this before, and he's just charging in, and learning along the way. I got a lot of respect for that! After all, isn't that how we all got started? You're doing great Zack.

In any case, with these encouraging words, I will be attempting to hang the engine up on 750lb pully system I installed on the garage ceiling (pic attached below) then try to get fitted onto an engine stand that I bought on amazon. If successful on the stand, attempt to rotate it and remove the oil pan. Then see if I would be able to remove the pistons without disturbing the crankshaft assembly.

I will then try to get the engine block and the head into my van and drive to a mechanic who is willing to inspect the cylinders for damage, and as well suggest any fix (such as honing etc).

(Btw thanks for the fuel filter/fuel pump correction!)