- Joined

- Dec 17, 2009

- Messages

- 210

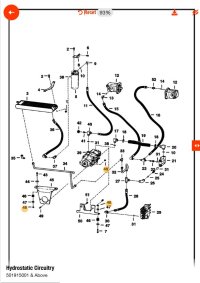

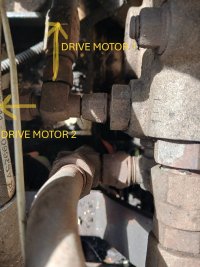

It appears from your pictures that you have a later model 743. You still have an inline hydraulic filter similar to the bronze filter, but it is in a different location. If I remember right the block that's in Markle's picture will have been moved to the side of the machine frame. There should be an inline filter in there, item 52 in this picture.