Yes, I do have the BOSS.give me a little while and ill dig them up. again does you syetme have a BOSS system or not?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Does anyone have a Bobcat 753 That could take a picture of wiring for me

- Thread starter theboss

- Start date

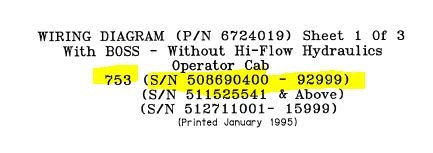

ok i just uploaded the one of the shop manuals. it looks like your SN predates the schematics in the manual i just uploaded. but the schematic should be closeYes, I do have the BOSS system.

Attachments

So, looking thru that manual i am following the hydraulic flow and they all show a diverter valve which I don't see anywhere. By this chart the 2 solenoids I have on top should my auxiliary solenoids. This picture is actually upside down from what i have. #11 would be at 7 o'clock position.ok i just uploaded the one of the shop manuals. it looks like your SN predates the schematics in the manual i just uploaded. but the schematic should be close

I just read through your original post. are you having a problem, or are you just concerned about a disconnected cable? I ask because many of these machines use a universal harness, and some functions are optional, based on how the customer ordered the new machine. My 753 has multiple connectors hanging loose and not connected to anything

So, I discovered my auxiliaries weren't working when I connected my plow for the first time. So, I lifted the cab and the wires coming out of the lever tube from the switches were just lying there no connectors or anything just strait cut wires. So, I can't figure out where the connection from the switch is supposed to go. the left and right switch have 3 wires coming out. the trigger has 2. The solenoids I have on top are 2 wire solenoids. I purchased the new updated auxiliary switch because my original was so corroded it didn't work. Now with the new switch the light lights up so all I have left is figuring out where these wires connect to and hopefully, I can angle my plow. I don't know there is a problem yet.I just read through your original post. are you having a problem, or are you just concerned about a disconnected cable? I ask because many of these machines use a universal harness, and some functions are optional, based on how the customer ordered the new machine. My 753 has multiple connectors hanging loose and not connected to anything

little_fellow

Well-known member

- Joined

- Oct 6, 2009

- Messages

- 205

I believe the diverter valve is right there in your own picture where you are showing the loose wires. the loose wires are from 2 solenoids and the solenoids are mounted on the diverter valve. I'm not a mechanic so I'm not 100% sure.508611787

From what I can tell I believe it is a 1990. I can't find any diverter valve which is what all the schematics I find have.

From what I can find online the diverter valve would be an aluminum brick but they were optional and I believe only used if you have rear auxiliary which I do not but I have no idea. This hydraulic setup is all new to me. My last one used clutches and only had a pump for the rams my problem I believe is none of the books cover my serial and I can't get any info from bobcat on this to find out where to start tomorrow I will be diving back into this and hooking everything back up and manually going to trigger the solenoids and see what happenesI believe the diverter valve is right there in your own picture where you are showing the loose wires. the loose wires are from 2 solenoids and the solenoids are mounted on the diverter valve. I'm not a mechanic so I'm not 100% sure.

I also had to replace my right side handle due to a corroded switch. New one shown in this photo.So, I discovered my auxiliaries weren't working when I connected my plow for the first time. So, I lifted the cab and the wires coming out of the lever tube from the switches were just lying there no connectors or anything just strait cut wires. So, I can't figure out where the connection from the switch is supposed to go. the left and right switch have 3 wires coming out. the trigger has 2. The solenoids I have on top are 2 wire solenoids. I purchased the new updated auxiliary switch because my original was so corroded it didn't work. Now with the new switch the light lights up so all I have left is figuring out where these wires connect to and hopefully, I can angle my plow. I don't know there is a problem yet.

Now that I'm looking at my machine to take these photos for you, I remember that the old one that I removed had loose wires Also. Are you loose wires simply cut or do they have weatherpack terminals crimped onto them?

Attachments

little_fellow

Well-known member

- Joined

- Oct 6, 2009

- Messages

- 205

It could be the control module is defective. I've had that problem before. Everything was working except the auxiliary part. Took me a long time to replace it because there is no way to diagnose the control module .unless you can switch it with one that is working. I checked everything I could before finally replacing the module with a new one. They are kind of pricy. This was back in 2017 and after I posted my progress on this forum, there was a forum member by the name of mmsllc claimed he had a parts machine that would probably have that exact part on it. Hope this helps. Good luck.So did some work on this. Manually powered the solenoids on top of the valve assembly and they both click. So I decide to start it and turn the auxiliary on and power a solenoid and no movement

Last edited:

Not entirely sure but I think since I powered the solenoid manually that would rule out everything to the valve block. But I only could power 1 solenoid at a time. I'm not sure how this system works because this is like a non existent 753 maybe both solenoids need powerIt could be the control module is defective. I've had that problem before. Everything was working except the auxiliary part. Took me a long time to replace it because there is no way to diagnose the control module .unless you can switch it with one that is working. I checked everything I could before finally replacing the module with a new one. They are kind of pricy. This was back in 2017 and after I posted my progress on this forum, there was a forum member by the name of mmsllc claimed he had a parts machine that would probably have that exact part on it. Hope this helps. Good luck.

Who knows.

In the manual when I look at the hydraulic flow operation the only time the auxiliary solenoids are mentioned is in the "optional diverter valve" section and I don't have a diverter valve

little_fellow

Well-known member

- Joined

- Oct 6, 2009

- Messages

- 205

I did a google search for 753 bobcat diverter valve and it's showing the valve where the 2 solenoids are mounted on.Not entirely sure but I think since I powered the solenoid manually that would rule out everything to the valve block. But I only could power 1 solenoid at a time. I'm not sure how this system works because this is like a non existent 753 maybe both solenoids need power

Who knows.

In the manual when I look at the hydraulic flow operation the only time the auxiliary solenoids are mentioned is in the "optional diverter valve" section and I don't have a diverter valve

Everything I found is an aluminum brick mounted right in front of the valve assembly above the right front wheel motorI did a google search for 753 bobcat diverter valve and it's showing the valve where the 2 solenoids are mounted on.

Attachments

little_fellow

Well-known member

- Joined

- Oct 6, 2009

- Messages

- 205

What I am trying to say is that the valve assembly is your diverter valve. I'm not sure what the aluminum one is, I don't have that on my 773 . You could be right . That looks like a Hydraulic pressure relief valve. Must be handy for when you need to relief pressure out of the system.Everything I found is an aluminum brick mounted right in front of the valve assembly above the right front wheel motor

Last edited:

Similar threads

- Replies

- 0

- Views

- 237

- Replies

- 12

- Views

- 1K