T-rustyfix

Well-known member

- Joined

- Aug 27, 2022

- Messages

- 68

I've come to the end of my tolerance for the modern fuel changes and resulting complications with the carburetor on my OMC 1200.

Every year when the fuel changes for winter here in the Northeast, I deal with rich/lean vapor lock issues and cannot find a balance with carburetor settings. I've replaced the whole zenith carb with a newly rebuilt one 3 times, installed a vapor lock arrestor filter and an aftermarket carb from Amazon, played around with the whole gamut of jets and fuel pressures, etc. etc.

Finally, I removed everything before the intake and ordered a fuel injector, fabricated my own intake from 1" steel pipe, installed the butterfly from the zenith, installed an aftermarket oxygen sensor and air fuel ratio gauge, hooked up all the wiring and high pressure fuel pump, and got the engine running.

Currently, my challenge is that the injector is open constantly, and I adjust the fuel ratio by opening the return fuel valve to decrease the pressure. I can set the correct fuel ratio by setting the throttle, and then the valve while watching the afr gauge and rpm meter. It runs better than ever, but I cannot change the throttle unless I get off the machine and turn the fuel valve as well.

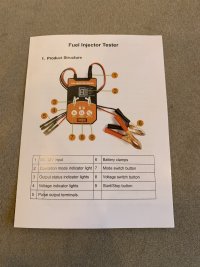

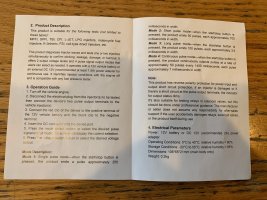

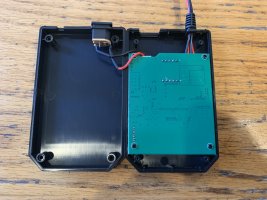

I toyed around with a 12v Pulse Width Modifier with limited success, but burned up a fuel injector as a result. I gather that the fuel injector solenoid overheated. I have looked online for a dedicated fuel injector driver, but all I can find is a fuel injector tester. I ordered one, but I do not have much confidence that the device will be able to handle the longevity I am requiring from it.

What I think I need is a throttle position sensor that works together with an adjustable

rate, 12v full-power pulse sending unit. I am a technical dinosaur with my hand stuck in a computer generation cookie jar. Please, anyone with some smarts in this direction deliver me from what I sense is an obvious answer just beyond my reach!

Every year when the fuel changes for winter here in the Northeast, I deal with rich/lean vapor lock issues and cannot find a balance with carburetor settings. I've replaced the whole zenith carb with a newly rebuilt one 3 times, installed a vapor lock arrestor filter and an aftermarket carb from Amazon, played around with the whole gamut of jets and fuel pressures, etc. etc.

Finally, I removed everything before the intake and ordered a fuel injector, fabricated my own intake from 1" steel pipe, installed the butterfly from the zenith, installed an aftermarket oxygen sensor and air fuel ratio gauge, hooked up all the wiring and high pressure fuel pump, and got the engine running.

Currently, my challenge is that the injector is open constantly, and I adjust the fuel ratio by opening the return fuel valve to decrease the pressure. I can set the correct fuel ratio by setting the throttle, and then the valve while watching the afr gauge and rpm meter. It runs better than ever, but I cannot change the throttle unless I get off the machine and turn the fuel valve as well.

I toyed around with a 12v Pulse Width Modifier with limited success, but burned up a fuel injector as a result. I gather that the fuel injector solenoid overheated. I have looked online for a dedicated fuel injector driver, but all I can find is a fuel injector tester. I ordered one, but I do not have much confidence that the device will be able to handle the longevity I am requiring from it.

What I think I need is a throttle position sensor that works together with an adjustable

rate, 12v full-power pulse sending unit. I am a technical dinosaur with my hand stuck in a computer generation cookie jar. Please, anyone with some smarts in this direction deliver me from what I sense is an obvious answer just beyond my reach!