Hi all,

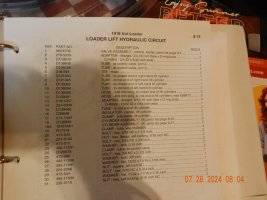

I have a 1992 case 1818 skid loader recently the tilt bucket was sluggish so I put a new hydraulic filter and new oil thinking maybe it may help. Today I was moving gravel and the tilt and the up and down is real week. I took it to a shop to put belts on it about eight months ago. It has never operated the same sense they put new belts, and when I got it back, the neutral lever does not work anymore sometimes if you have it in neutral and you push the levers to go forward it will still go forward, he told me that the pivot points are wore out on the motors. I'm not real familiar with that. Any ideas if that has anything to do with the bucket lifting or tilting I do have a repair manual I just really don't understand the adjustments. I have about 1300 hrs on the machine.

I have a 1992 case 1818 skid loader recently the tilt bucket was sluggish so I put a new hydraulic filter and new oil thinking maybe it may help. Today I was moving gravel and the tilt and the up and down is real week. I took it to a shop to put belts on it about eight months ago. It has never operated the same sense they put new belts, and when I got it back, the neutral lever does not work anymore sometimes if you have it in neutral and you push the levers to go forward it will still go forward, he told me that the pivot points are wore out on the motors. I'm not real familiar with that. Any ideas if that has anything to do with the bucket lifting or tilting I do have a repair manual I just really don't understand the adjustments. I have about 1300 hrs on the machine.