Having an issue with a skid steer I bought a while back. I expected to have to do some maintenance and repairs on it since it is a pretty old beast (2622 hours now). I recently repaired a leaky left side lift and tilt cylinder and those no longer go down over time.

Ever since I've owned the machine, it has made a funky whirring noise when rotating around the axis (full forward right, full back left - and vice versa). After making the repairs to the hydraulic cylinders, I've used it a bit, but have noticed that I would lose power in the tilt/lift/aux hydraulics as well as on the left and right wheels intermittently. I have not yet been able to identify which conditions bog it down. The engine seems to be running totally fine when this happens, and revving it higher does not help. When I noticed it, I hopped out and topped off the fluid, in hopes that I was a bit low. That did not seem to help, although after letting the machine sit for a few minutes, things worked well enough that I was able to drive back to where I park the machine. I had to go up a somewhat steep slope on the way and bogged down to a standstill, dropping the revs and edging my way up allowed me to continue up the hill. Engine did not seem to have trouble even at low revs.

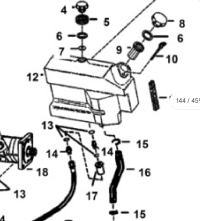

Any thoughts on what this may be? A quick google search revealed that it may be a hydraulic filter/hydrostatic pump issue. I wonder if I introduced some contamination when rebuilding the cylinders that might have blocked up the filters - I thought I worked pretty cleanly.

Thanks

Ever since I've owned the machine, it has made a funky whirring noise when rotating around the axis (full forward right, full back left - and vice versa). After making the repairs to the hydraulic cylinders, I've used it a bit, but have noticed that I would lose power in the tilt/lift/aux hydraulics as well as on the left and right wheels intermittently. I have not yet been able to identify which conditions bog it down. The engine seems to be running totally fine when this happens, and revving it higher does not help. When I noticed it, I hopped out and topped off the fluid, in hopes that I was a bit low. That did not seem to help, although after letting the machine sit for a few minutes, things worked well enough that I was able to drive back to where I park the machine. I had to go up a somewhat steep slope on the way and bogged down to a standstill, dropping the revs and edging my way up allowed me to continue up the hill. Engine did not seem to have trouble even at low revs.

Any thoughts on what this may be? A quick google search revealed that it may be a hydraulic filter/hydrostatic pump issue. I wonder if I introduced some contamination when rebuilding the cylinders that might have blocked up the filters - I thought I worked pretty cleanly.

Thanks