Badwhiskey7

Member

- Joined

- Nov 29, 2024

- Messages

- 5

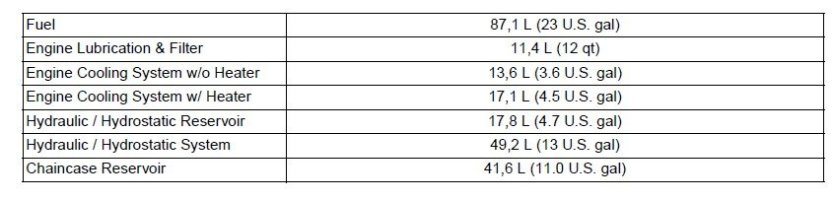

Ok, this is directly about a T190 but crosses over to ALL bobcat Skid and Track loaders plus probably other equipment. Point in fact, some of these items arent listed or at least clearly listed in manual. My theory is if it breaks, you may just buy a new one hence the lack of information.. Obviously, we all change our oil and hydraulic filter, plus oil water separator religiously right? Well, how about the final drive oil? Its very important and is usually dry once we get to it. Besides it being a b!7(h to get to. Well, theres more folks!! Theres a main case filter directly below seat, plus two more smaller filters below each kneecap for the drives. Just wanted everyone to be aware theres more general maintenance that is highly important ill bet alot of us didnt know about. Jus trying to keep everyone's equipment up to par. Theres also dumb sh!t like hyraulic oil cap vent needs replacing, you swap the drive sprokets every time theyre off like rotating tires, tracks as well. And do actually buy NEW QUALITY air filters on a regular basis, not just blow out. Especially important with turbo models as they need consistent intake pressure to stay cool. Hope this helps somebody, and im sure im missing a ton. Have a wonderful Bobcat day!