Hi, I have an S175 that I purchased about a year ago for use around my property, the unit had been serviced 100 hours prior so I have not done any fluid changes yet. I do however need to top up the hydraulic fluid as there is a leak in my log splitter and I am not sure what fluid they used but it's likely the bobcat stuff. Unit is in the pacific nw so neutral climate.

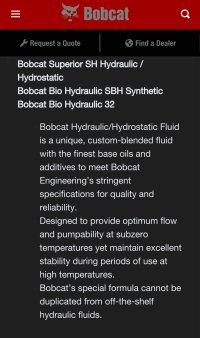

So the question is, I have two new 5g barrels of AW46 fluid left over from a marine hydraulic system. Is there any issue with using that to top off the bobcat?

The specific fluid is Chevron Rando HD46.

Longer term could I use HyGaurd in the bobcat? I like the idea of only using one fluid type for the bobcat, tractor and miniex.

Thank you!

So the question is, I have two new 5g barrels of AW46 fluid left over from a marine hydraulic system. Is there any issue with using that to top off the bobcat?

The specific fluid is Chevron Rando HD46.

Longer term could I use HyGaurd in the bobcat? I like the idea of only using one fluid type for the bobcat, tractor and miniex.

Thank you!