The screw driver getting pulled in... That's still power applied, right? That's normal and correct operation.

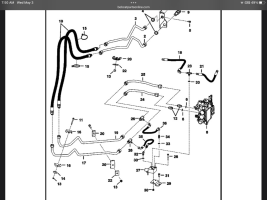

Yes under power. I was going to pull the valve that the solenoid was on but it appears that hydraulic oil would need to be drained. I have been trying to troubleshoot and narrow down. I don't know a thing about these machines. Any input is appreciated. If replacing parts require draining oil, I kinda would like to replace whatever affordable parts that could be the issue especially if I have to remove control valves and other parts from the machine.

To recap:

3 years ago when I acquired the machine the Auxiliary Hydraulics only worked in one direction but when on did not inhibit any other hydraulic function. I have not used the Auxiliary Hydraulics since then. Actually the machine sat unused for a couple of years because it kept locking up hydraulics because of a seat bar issue that drove me nuts. Last year I sent the control board to be looked at and it was the problem. It was repaired and no more issue with seat bar.

Over last year I used machine lightly to move pallets, and some bucket work. No issues with lift or tilt.

Recently I acquired a 709 to dig a few trenches around the property. In preparation for the 709, I turned on the hydraulics to see if they bogged down the engine in both directions. I was curious if the auxiliary hydraulics still only worked one way. After doing that for only a minute or two, I noted the lift and tilt was not working as designed. In order for lift and tilt to function, I had to have the right hand trigger pulled and auxiliary hydraulics in reverse. Without the aux hydro in reverse and turned on the engine was loaded/bogged down and lift and tilt would not work.

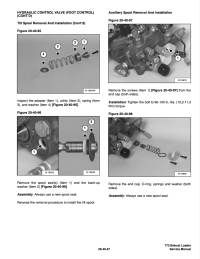

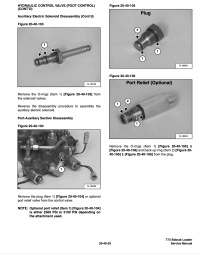

Yesterday I removed what I thought was the forward and reverse aux hydro spools/valves/whatever and switched them. The lift and tilt worked as designed until I turned on Aux Hydraulics and then engine bogged down and lift tilt no longer worked. This time, turning on Aux Hydraulics, pulling the trigger and trying to engage forward or reverse did not relieve the bog down nor allow the lift or tilt to function as designed. I was able to turn and pull up on emergency relief valve and while holding up get the lift and tilt to work. I then took out the aux hydro spools/valves/whatever and put them back where they were originally. After that the lift and tilt once again functioned as designed. I did not turn on Aux Hydraulics again to see what would happen.

Today I tested the solenoid for the Front Aux Hydraulics Pressure relief. The solenoid appears to function normally.

I guess it is possible if a machine was hooked up to the Auxiliary Hydraulics it would act different than no machine but I doubt it.

Furthermore, when pressing the relieve pressure on the left upper control panel and holding it, it stalls the engine as designed.

Any input appreciated. Thanks in advance.