schemasservice

Member

- Joined

- Aug 25, 2024

- Messages

- 11

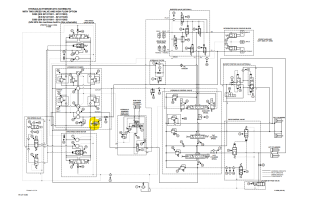

Good morning. I have been racking my brain over my 2004 S250 for quite some time. It will run a grapple or other low flow hydraulic cylinder from aux just fine. I get 3100psi at the connectors with a gauge. Problem comes when I'm trying to run a snow blower, or brush cutter. It will spin it up, but when it gets a little load, it slows it down, even stops it sometimes. I have high flow, and pushing the high flow button does nothing. The high flow light comes on, but no difference in hydraulic action. It has been this way for years. I attached the schematic from the service manual. It shows what they are calling a "dump valve ON/OFF" on the pump. The manual has nothing else about this valve listed. Nothing about removing, or testing it. I am assuming this is the high flow valve, and it dumps excess flow when high flow is not engaged. I have no power / actuation of this solenoid when high flow is on or off. Again, I am just assuming thats what this valve is for, as there is nothing else in the schematic for a high flow valve. I can't find any info online, or in Bobcat's wonderful service bible about diagnosing this system. Hoping some one here has some knowledge on this. Thank you. Brian