I purchased a 1985 743 with the engine completely torn down. I was told it overheated and cracked the head. It came with a new head. I purchased a complete rebuild kit and dropped off the block at a machine shop. They cleaned the block and installed new liners and front main bearing. Cylinder 3 had a weird ridge in the bore almost like they stopped boring half way through the cylinder. They also mag fluxed the head and said nothing was wrong with it. I installed the new head anyways. I think their overheating issue was the 20 pounds of dirt that I cleaned out of the radiator. It was so bad you could not see any light from the fins. I got the engine put back together and I just need to time the injector pump. It came with out any shims. My main question, that i cant find anywhere, is that i have two fuel lines coming from the tank. I take it one is supply and one return. The supply line is pretty simple. Tank to filter then pump, but i cant figure out where the return hooks up to. Any help will be greatly appreciated. I'm shooting for the first start this weekend. Hopefully i don't have to spend another small fortune on the hydraulic side.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rebuilding a 1985 743 with a Kubota 1702 and i have a few questions.

- Thread starter Junkers

- Start date

Help Support SkidSteer Forum:

brdgbldr

Well-known member

- Joined

- Jun 1, 2012

- Messages

- 1,194

I would suggest taking a look at the parts catalog. Put in your serial number and then search "tank". You should be able to find the fuel system schematic. (The new parts catalog sucks but it still works ).

partscatalog.bobcat.com

partscatalog.bobcat.com

Bobcat Parts Catalog - Find Diagrams for Your Equipment - Bobcat Company

Locate all parts and component information about your Bobcat equipment with detailed visual diagrams and illustrations with parts numbers and add to your list.

The return line goes to injector number 4's return line. There will be a barb at the end, just run it to that spot.

You will have a bleed screw on the pump with a small barb too, this goes ti injector #1, then to two then three then 4, it's not a hard setup once you see it.

As for shims, have you spoken to your local kubota dealer? generally i believe there are 2 shims, but in the manual it tells you how to work out how many shims you require to get the correct timing.

V1702 engines generally run composite head gaskets, ensure you re0tension it after 6-10 hrs of run time or it is likely to leak.

You will have a bleed screw on the pump with a small barb too, this goes ti injector #1, then to two then three then 4, it's not a hard setup once you see it.

As for shims, have you spoken to your local kubota dealer? generally i believe there are 2 shims, but in the manual it tells you how to work out how many shims you require to get the correct timing.

V1702 engines generally run composite head gaskets, ensure you re0tension it after 6-10 hrs of run time or it is likely to leak.

Chris 8603

Well-known member

- Joined

- Aug 4, 2023

- Messages

- 114

I have a complete service and parts manual if you need any help on the timing setupI would suggest taking a look at the parts catalog. Put in your serial number and then search "tank". You should be able to find the fuel system schematic. (The new parts catalog sucks but it still works ).

Bobcat Parts Catalog - Find Diagrams for Your Equipment - Bobcat Company

Locate all parts and component information about your Bobcat equipment with detailed visual diagrams and illustrations with parts numbers and add to your list.partscatalog.bobcat.com

Well I attempted to time the injector pump with two new shims as the starting point. The 1702 manual says it should start flowing at the FI timing mark. Well after a while of bleeding the injector pump. It starts flowing way late. I removed all the shims and now it seems to start flowing at the correct timing mark. Ever seen an injector pump requiring no shims? It it possible that its just wear on the cam and pump? I think the pump is functional wear wise as it shoots the fuel up 6" to 8" when turning over with the starter.

Just give it a test run, if it runs right, it must have not had shims from the factory.

I am not the one that builds these engines, so i can't really comment on how many times shims are not needed, but these engines seem to be quite forgiving.

I am not the one that builds these engines, so i can't really comment on how many times shims are not needed, but these engines seem to be quite forgiving.

I got enough of the 743 back together to get it started. I made a mess of every single fluid. These new fire proof fuel cans are a joke. I had to drill a vent hole in a new can just to get it to dispense fuel. After bleeding the fuel lines she starts right up and shot up to 2k rpm. I have a hand held tach. It appears someone screwed the throttle plate arm stops most of the way in. I unscrewed it back out and get about 800-900 rom at idle. The engine runs for a few seconds and dies. I think i still have air in the fuel system. Then i notice the engine bay filling up with oil. One of the hydraulic lines were loose on the top of the hydro unit. I got the line tight and gave up for today. My second person had to go home.

Chris 8603

Well-known member

- Joined

- Aug 4, 2023

- Messages

- 114

Good luck on getting back the rest of the way. I believe you about have it !!!

I was just going to message you that mine only has 1 shim in it, but I have saw them run with no shims. Worst case would be you have to pull it and add shims. SO glad it didn't run away from you when it started that way.

Good luck

I was just going to message you that mine only has 1 shim in it, but I have saw them run with no shims. Worst case would be you have to pull it and add shims. SO glad it didn't run away from you when it started that way.

Good luck

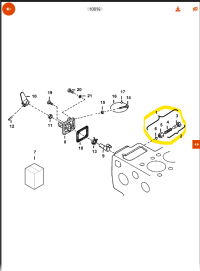

I think that i got everything squared away on the bobcat. I still have to get the air out of the fuel system and set the min and max adjustments on the throttle plate. But there is one more adjustment on the injector pump that im unsure what it does and how to adjust it. Its the adjustment screw/bolt on the backside? of the injector pump. Its part 1 in the parts diagram that ill try to attach and it says its a idle assembly. I do not know a good starting position for it as i purchased this bobcat with everything torn down already.

Attachments

Thanks. I was standing back by the engine and had another person turn the key to start it. As soon as I heard the engine starting to rev up I hit the fuel shut off to kill it. As with any new/rebuild diesel engine, I always have the back up emergency stop 2x4 sitting on top of the engine.Good luck on getting back the rest of the way. I believe you about have it !!!

I was just going to message you that mine only has 1 shim in it, but I have saw them run with no shims. Worst case would be you have to pull it and add shims. SO glad it didn't run away from you when it started that way.

Good luck

Chris 8603

Well-known member

- Joined

- Aug 4, 2023

- Messages

- 114

Lol!! I here ya. I had Detroit run away one time. I learned to have a backup for the backup from that expensive screw up!!! And the fact I didn't need to mess with those type fuel rail systems