chrisepp

Active member

- Joined

- Jun 15, 2021

- Messages

- 35

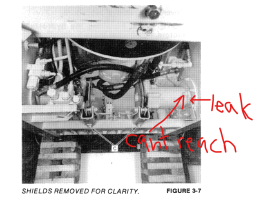

Found another issue with the L555 skidsteer we got. (After all the digging, it was very poorly maintained sadly...). One of the hydrostatic motor bolts were loose and it leaked hydraulic fluid, and also let water in. (one was totally loose) I tightened it back up (front bolt) but it still leaks. I can't get to the rear one because the fuel tank is in the way. Anyone know if the fuel tank can be loosen and shifted enough to get at the rear bolt to tighten it? And will it need to come off totally and have RTV put in there to seal it properly? (or backed off enough we can get some in all the way around? Really hoping this doesn't need dropping the tank. Have not found any details on that, doesn't seem to cover the fuel tank at all in the service manual.